NEED SAVINGS? … DON’T JUST CUT COSTS

It’s an all-too familiar scenario: Company leaders, alarmed at a sudden decrease in profits, issue a decree to curb business trips, count paper clips, or trim headcounts.

They’re clearly thinking that the quickest way to boost profits is to cut costs. But, they’re thinking wrong! Let’s explore why this might be …

All costs are not the same

In every business, there are two basic types of costs: Those that are necessary to sustain or grow the enterprise (let’s call these “value-added”), and those that do not contribute to the bottom line (aka “wasteful” or “non-value-added”).

Unfortunately, the wasteful costs are often the hardest to see, as they are hidden deep inside company processes and ways of doing business. So, company executives focus on the things that are right in front of them—such as travel, office supplies, or payroll. But these are the very costs that do contribute to the bottom line, so it becomes a short-term fix that can actually hurt the business in the long run.

It’s like putting a bandage on a wound but ignoring the internal bleeding.

The cost of poor quality

By focusing on the wrong kind of costs, you will never find the true root of your problem or sustain the gain. You will waste time trying to fix items that are not broken, which can negatively impact company profits or your competitive edge.

While it’s unrealistic to expect to eliminate all of your waste and inefficiencies, even a small recovery of those costs can create a big impact.

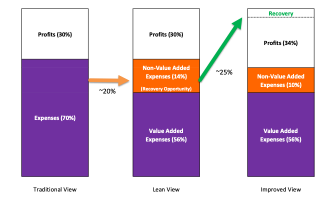

Let’s say a company’s total costs are 70% of revenues, for a profit of 30%. But one-fifth of those costs, or 14%, are non-valued added. So, if the company could recover just a quarter of that wasteful spending—shrinking those expenses to, say, 10%—the profit would immediately rise to 34%.

And, even better, the company would have eliminated the right kind of costs!

A real-life example of cutting wasteful costs

The Dorsey Group recently worked with a manufacturer that was concerned about costs of their shipping materials. They were spending 20% more on cardboard than was budgeted. Their initial reaction was to pressure the cardboard vendor for better pricing, for they assumed that’s what was causing the overage.

But after a careful assessment of their shipping department, we discovered that they had an unacceptable amount of returns due to self-made errors. The reshipment of orders was causing the additional cardboard costs. We implemented a few procedures to address the issue, and the cardboard cost came back to budget.

Impact on the bottom line

If you can produce for less, you now have two choices with what to do with those savings: You can keep the margins the same but lower prices, giving you a competitive advantage; or you can keep the price the same but raise margins, giving you more profits and/or reinvestment opportunities. Either way, you win!

Eliminating wasteful costs also has the effect of becoming a preventive measure; you are literally preventing these costs from continuing to hurt your bottom line.

How to recover wasteful costs

So, how do you go about trying to find and eliminate your non-value-added costs?

Enable your workforce! Get everyone to start thinking differently about your processes. Let them know they can make a difference and that they will be asked to assist with identifying, prioritizing and solving issues throughout your organization.

- Enlist your entire workforce. Have teams create a process map that lays out their work activities, key indicators with expectations, and frustrations and performance killers.

- Create a briefing structure. Develop a scorecard that aligns expectations and provides daily and weekly feedback on performance across all levels of the organization.

- Document in real time. Engage all employees in the collection, analysis and stratification of data. Turn that data into information that leads to decision-making based on evidence.

- Become knowledge-based. Make your employees accountable and give them ownership so that knowledge is created, used and acted upon.

Long-term sustainability

Once you’ve done the work of eliminating non-value-added costs, you can’t just assume that everything will go smoothly. That would lead to complacency, which—just like waste—can harm a business in the long term. Therefore, you must always be on the lookout for waste that can lurk within or creep into your organization.

So, how are you going to address your bleeding problem? With a Band-Aid?

Or with a deeper, preventive remedy that can be found in a solid performance improvement program?

The Dorsey Group can help unleash your team’s potential and power peak performance. For more information, contact us at www.TheDorseyGroup.org or (954) 629-5774.